Club Lotus Australia is full of interesting people who are up to interesting things with interesting cars. We think that’s wonderful, so we’re going to share their stories with you here!

If you’d like to share your story on the club website, just send Seth a quick email at [email protected]

In this post, we rejoin Geoff Winder as he fabricates a flywheel and finds a clutch for his Lotus Esprit VQ project.

Read Part 1 here.

Read Part 2 here.

By Geoff Winder

So, now that we have a gearbox bolted to the engine, we need a flywheel and a clutch to go with it.

I started by contacting a number of machine shops to get a complete one fabricated, but they either wanted stupid amounts of money or were booked up until 2027. So I started to think, how hard could it be…

There are no manual flywheels for the VQ30DET. The closest I could get was a Maxima flywheel, but even that didn’t fit. However, between the timing ring from the auto flex plate that the VQ30DET came with and the Maxima manual flex plate I could get something to work.

The Maxima setup is front wheel drive, so Nissan pushed the starter and timing gear back into the engine to save space (compared to the Cima’s rear drive setup on the VQ30DET). So, I need to adapt to the Maxima spacing.

The first step was to make this up.

Now don’t try this at home children. A router with a tungsten bit slowly pushed down its slides cut a nice round rebate for the timing sensor to be set back into the block. And, actually, it made a beautiful cut.

All lined up now.

I could have used the Maxima flywheel (the cast iron part just at the bottom of the picture). However, the largest clutch I could get was really not up to the potential power of the VQ30DET. Anyway, using something off the shelf is just too easy…

Remember my poor little milling machine? Well, look what I have in store for it! A nice piece of premium grade cast iron.

The plan is to machine the side that bolts up to the Maxima flex plate, then machine the other side on the lathe.

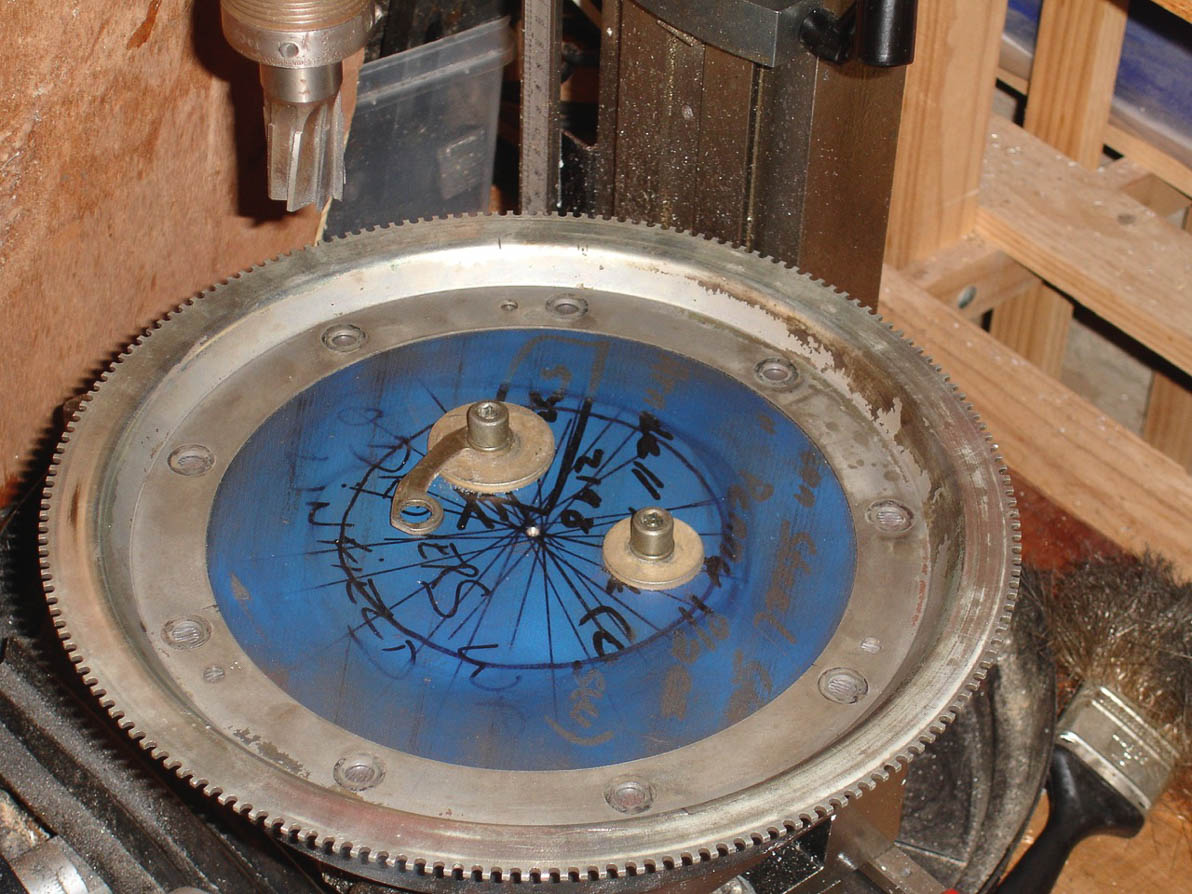

Lining up timing ring for bolt and dowel holes.

Milling machine’s work is done.

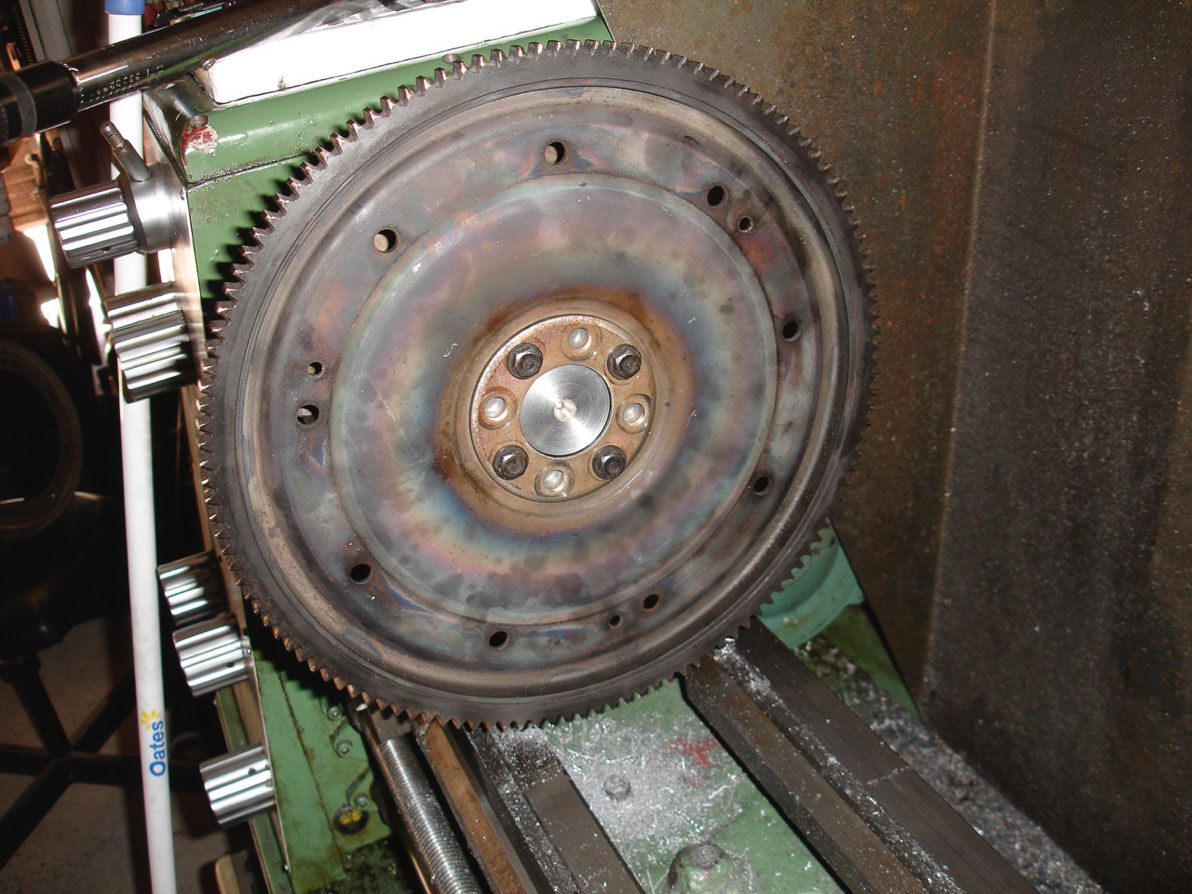

The next step was to make this little copy of the end of the Nissan crank so that I could bolt the Maxima flex plate in the lathe.

Here it is setup in my father-in-law’s lathe.

Time to make cast iron swarf (iron filings really).

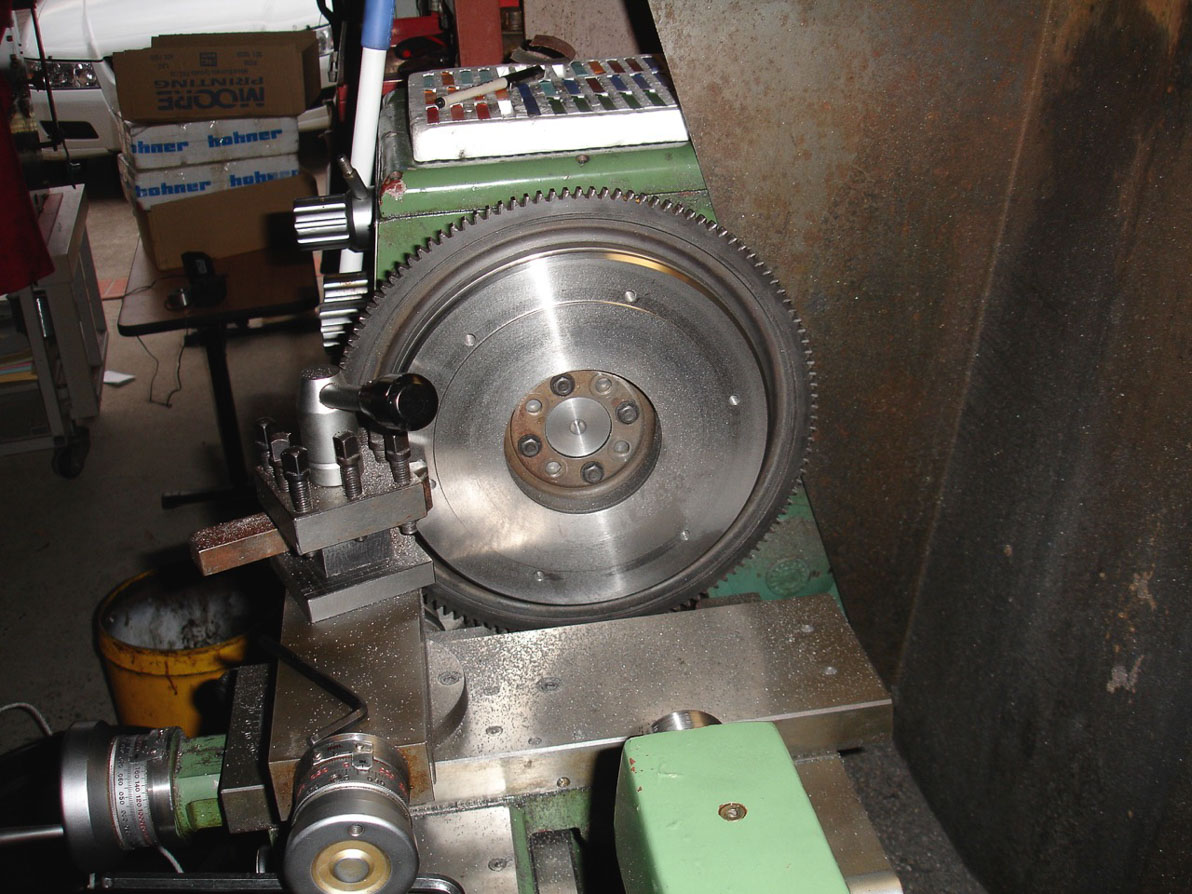

4 hours of machining later.

Here is the finished product. It weighs only 8.5KG, BUT it looks very small. What are you doing, you ask?

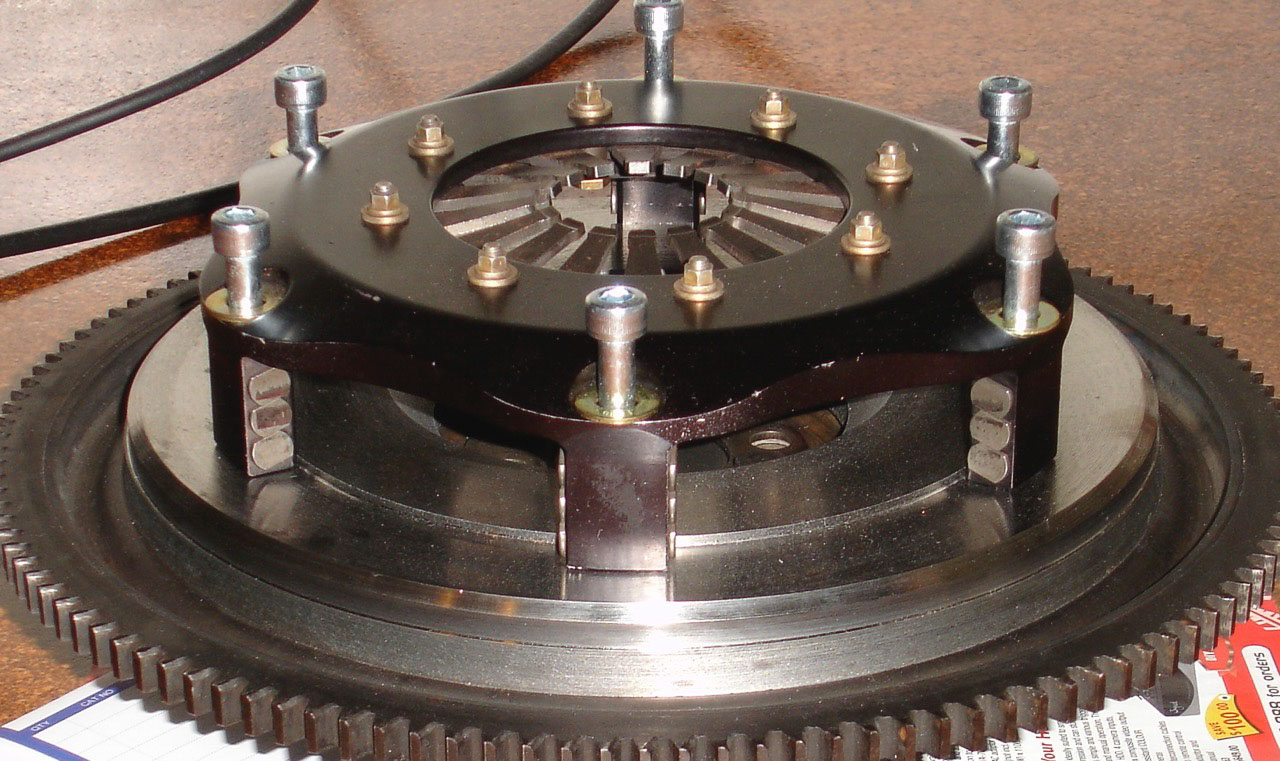

Ever heard of an American past time called Nascar? This triple plate button clutch, set up for well over 1000HP, was used in a few races and then discarded to eBay for 1/4 of its price. I will use it as a twin “organic” plate setup that should easily handle the VQ’s power and give reasonably light pedal pressure.

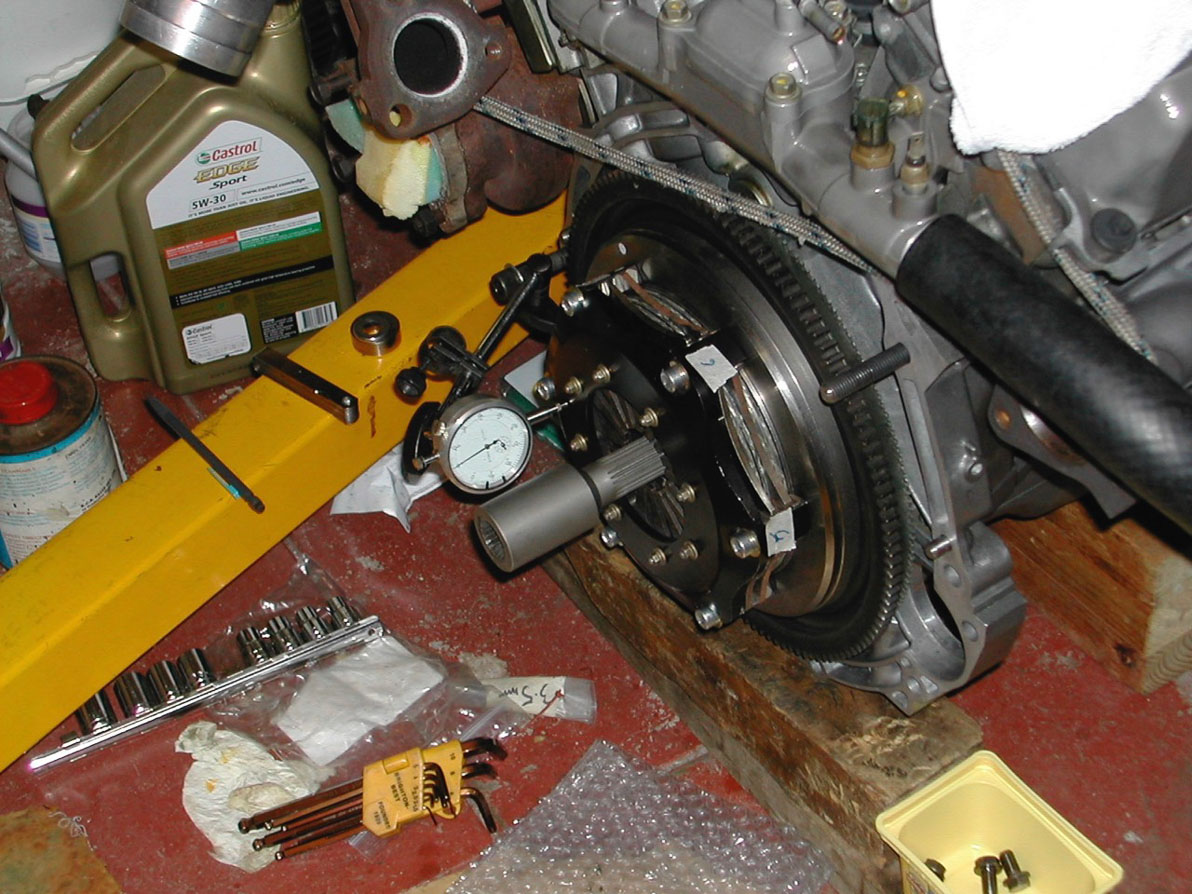

After Dynamic balancing, the flywheel is ready. Quick check of alignment, good to go.

Everything bolted up and ready for the longest release bearing in history.

Stay tuned as we continue this unusual and fascinating project with part 4 – coming soon!

One Comment on “CLA Build Stories: Part 3 of the Lotus Esprit VQ Build – Fabricating a Flywheel and Finding a Clutch”

Hi Geoff,

Once people read your story, and especially what you rather than others have done, I’m sure at Lotus2019 you are well and truely in line for the Mechanical Excellance Trophy.

Regards Rob Barker.