Club Lotus Australia is full of interesting people who are up to interesting things with interesting cars. We think that’s wonderful, so we’re going to share their stories with you here!

If you’d like to share your story on the club website, just send Seth a quick email at [email protected]

In this post, we catch up with Ashton in July of 2015, to find out more about his journey with the Tuft’s Eleven.

TUFT’s Eleven May & July, 2015

Well, I may have taken a while to get there, but I think finding Geoff Wheeler was a good thing!

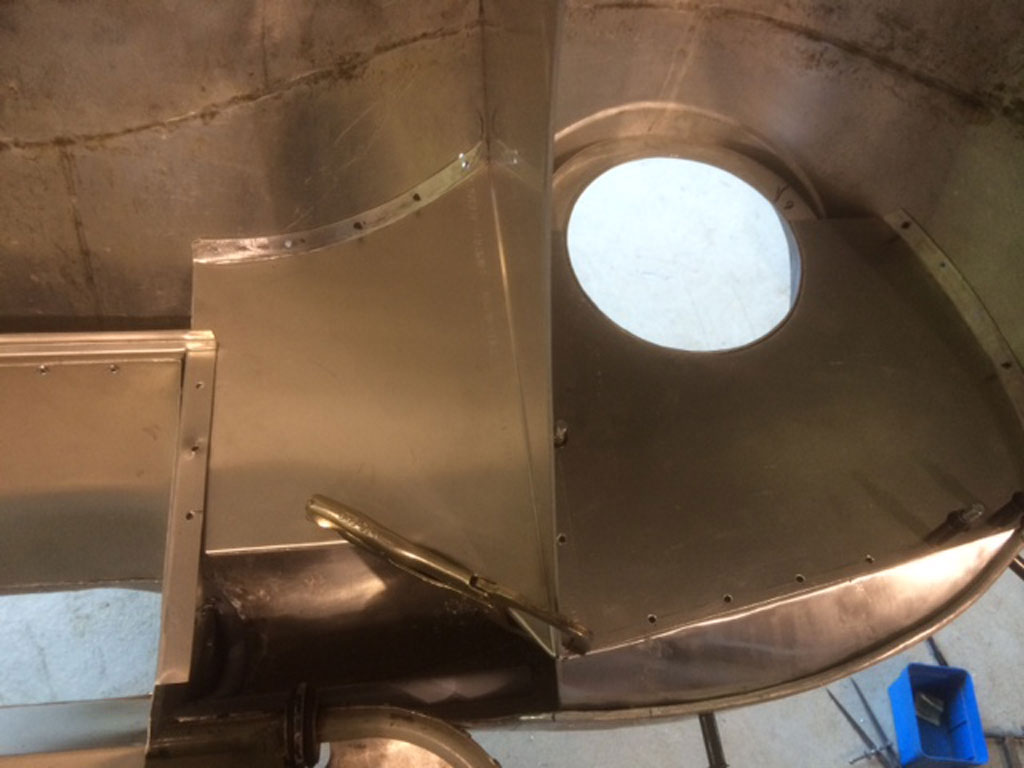

While I have been away, he has got the car to where it needed to be about three months ago, so I am feeling a lot happier with progress, although the likelihood of getting it ready for October are pretty slim to say the least! For this update we can see work completed on the inside of the clam with both mudguards formed up, work completed on the offside wheel arch and some detail of the cowels for the headlight and radiator.

24th July 2015

Blimey, it’s been a while…. and not a lot has happened! Being made redundant in June caused me to stop spending money on the car for a few weeks, but now that that particular problem has resolved, I can move on to bigger ones – like how to get the engine built! This is now the critical path for the Eleven rebuild.

Originally Bruce’s son Nick was going to do it, but he has other competing priorities so I think I need to find an alternative. The visit to Trevor’s shed allowed me to get in touch with Lou Russo, and he could be a good find, except that he’s in Melbourne! One or two other options exist in Sydney which I need to explore, and I need to get Geoff back on the case to get the bodywork finished.

Fun fun fun… decisions, decisions, decisions. I’m heading up to see Geoff next week, so will try to get some more recent photos!

27th July 2015

OK, this should make you laugh.

Having explored the various third party engine builders options available to me, I had concluded that my best bet was either to send it to Melbourne or back to the UK. So, I sent a note to the Eleven Owners Group (no such thing exists, but there is an email list I have of some of the more helpful owners, who have proven to be invaluable in their assistance, knowledge and opinions!). Ed Holly (green S2 Eleven, Elan S3, Elite, and S2 Seven as well as a BT6 for those who’ve not had the pleasure of meeting Ed) has offered to allow me to use his facilities and pick his brains on the two Climax engines he has built for his Elite and Eleven.

So, I am going to build it myself (with a little help from Ed).

Before you fall off your seat, I have also just spent most of this afternoon with Bruce Mansell, who knows more about these engines than pretty much anyone in existence. He thought it a good idea, and has offered his kind support for the project, which is as well, because it’s certainly not a simple “bolt it up and she’ll be right” build!

The first challenge he gave me was to get the bearing cases line bored, and the bores reamed to accept the liners I have bought from Tony Mantle in the UK. Take the block to Parry’s in Arncliffe, he suggested, although unfortunately they closed up shop last year. Apparently there is a guy out in Penrith who has developed some of the requisite skills, so I am heading to Ed’s tomorrow to discuss in more detail.

Other than that, I also have to order a sump from Tony Mantle, a high volume oil pump from Glyn Peacock, and a set of replacement capscrews for the sump. Then I need to get the oilways redrilled according to Bruce’s specifications so the oil flows the right way through the oil cooler and filter – sounds simple, but probably isn’t!

Next I have to work out the bearings required – the mains are possibly Ford, with the big ends BMC, or it might be the other way around. And then get a water pump, nose pulley, timing chain, dynamo, speedo drive (off said dynamo) and probably a host of other bits I have yet to find I need.

Ah well, another few steps forward and a few more back – that’s projects for you. At least I have been able to give Geoff the go-ahead to finalise the bodywork, so I’ll be up there on Wednesday with a bootfull of bits for him to tinker with.

See you in September!

Catch up on previous episodes of this build journal in part 1 here, part 2 here, part 3 here, part 4 here and part 5 here.

- Detail of the offside wheelarch

- Detail of the cowels for the headlight and radiator

- The inside of the clam with both mudguards formed up